Revolutionising Route Selection Through Digitisation

In the intricate world of synthetic organic chemistry, the journey from conceptualizing to producing materials has traditionally hinged on the expertise and intuition of chemists. This human-centric approach, while innovative, is fraught with limitations, particularly in the pharmaceutical industry where the stakes are high, and the demand for efficiency is relentless.

One of the primary challenges in pharmaceutical development is the synthesis planning for Active Pharmaceutical Ingredients (APIs). This process begins with identifying the pharmacophore, the essential features necessary for a molecule to interact with a biological target. Researchers propose various target molecules, each with potential therapeutic benefits, and develop preliminary synthetic routes to test these compounds. However, the path from laboratory to commercial production is long and complex, often requiring iterative refinement of these synthetic routes to meet the demands of large-scale manufacturing and regulatory compliance.

Traditionally, selecting the optimal synthetic route for API production involves a myriad of factors. Safety, environmental impact, legal considerations, economic viability, process control, and throughput all play critical roles. This decision-making process relies heavily on the experience of process scientists, who must synthesize vast amounts of data from laboratory trials, literature, and modelling tools. However, human bias and the inability to process large datasets effectively can lead to suboptimal route selection.

This is where digitisation steps in as a game-changer. By embracing digital tools, the pharmaceutical industry can overcome the inherent limitations of human-led synthesis planning. Digitalisation enables the systematic capture, organization, and dissemination of knowledge across projects, leveraging centralised databases and collaborative platforms. These systems allow for the integration of diverse data sources, from experimental results to theoretical predictions, providing a comprehensive overview that surpasses individual human capabilities.

One significant advantage of digitisation is the ability to apply advanced algorithms to the entire dataset. These algorithms can reveal insights that may be missed by human analysts, uncovering optimal synthetic routes that balance all necessary criteria. For instance, network metrics can identify the most promising pathways, ensuring that no viable options are overlooked due to unconscious bias or data handling limitations.

Figure 1: Viewing the problem from different perspectives can improve our understanding

Moreover, digital tools facilitate real-time collaboration among scientists, enhancing the collective intelligence of research teams. By storing chemical knowledge in graph databases, researchers can access and contribute to a shared repository, enriching the metadata with continuous inputs. This collaborative approach not only speeds up the synthesis planning process but also fosters innovation by exposing researchers to a broader array of ideas and methodologies.

The benefits of digitisation extend beyond the laboratory. For pharmaceutical companies, digital tools streamline the transition from small-scale production to commercial manufacturing. They enable more efficient scaling of synthesis processes, ensuring that APIs can be produced at the required quality and quantity to meet market demands. Additionally, the ability to rapidly evaluate and adapt synthetic routes reduces the time and cost associated with drug development, ultimately making medicines more accessible and affordable for patients.

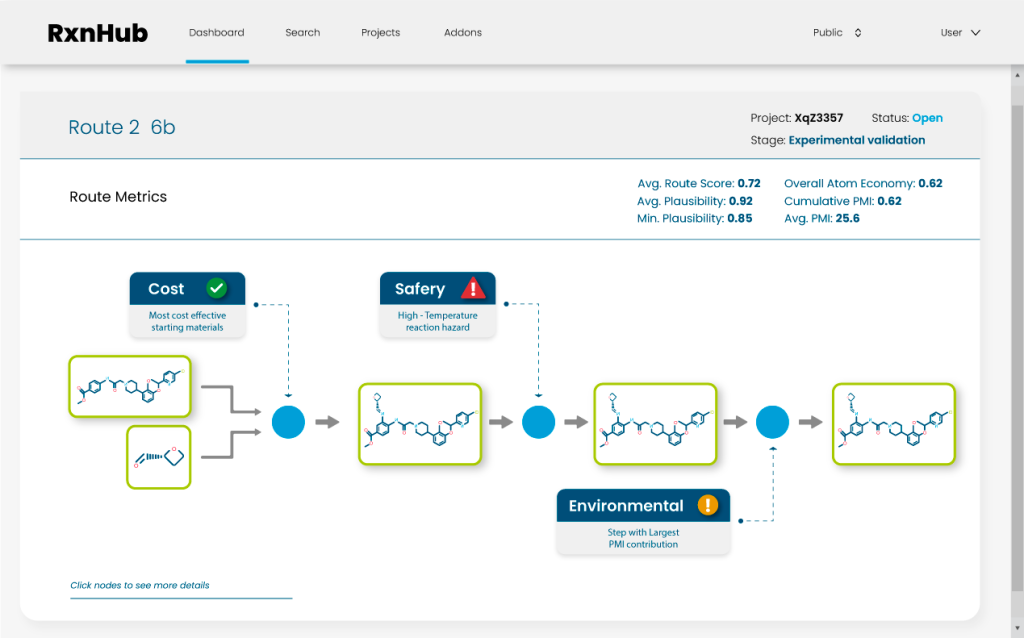

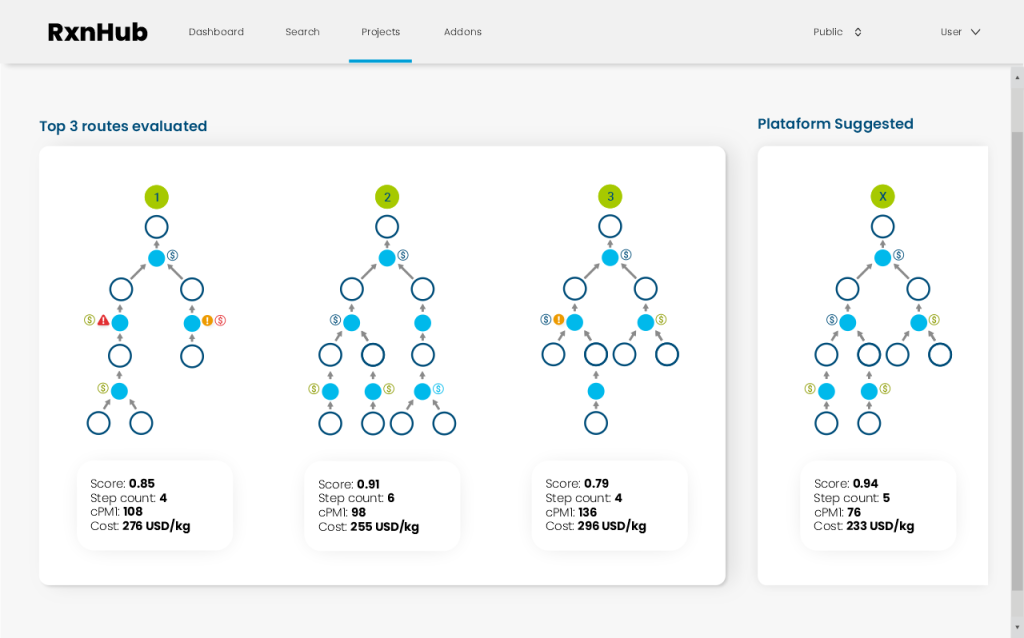

Figure 2: Viewing the problem from different perspectives can improve our understanding

In conclusion, digitisation is not just an enhancement but a necessity for the pharmaceutical industry. It transforms the traditional synthesis planning process, mitigating human biases, and leveraging the power of data and algorithms to identify the best possible routes for API production. By adopting digital tools, pharmaceutical companies can achieve greater efficiency, foster innovation, and ensure that life-saving medicines reach patients faster and at a lower cost. This shift towards a digital paradigm is essential for meeting the ever-growing demands of modern healthcare and delivering better outcomes for patients worldwide.

How our platform solves these key challenges

Our platform is designed to transform how synthesis planning is approached by offering a versatile solution that meets a range of needs. It features a robust public database of molecules and reactions, which will be continually updated through collaborations with universities and chemistry organizations. This ensures that users have access to a wealth of information for both educational and commercial applications. On top of this, our platform provides a private layer where companies can securely integrate their own data from electronic lab notebooks and other internal sources. This private space allows for the addition of insights from retrosynthesis software and exclusive databases, all while keeping sensitive information safe and within company control.

The platform excels in fostering team collaboration with its intuitive workflow management tools. Users can create projects centred around target molecules, with the system automatically pulling in relevant data to build a network map of potential synthetic routes. Scientists can then work together to analyse and refine these routes, benefiting from features like data enrichment, cost estimation, and automatic safety and environmental assessments. Additionally, while future plans include connecting with purchasing databases and robotic platforms, the current tools are already set to enhance every stage of the synthesis planning process, making it easier to find the best solutions efficiently and collaboratively.